Grounding a Campervan Electrical System

- Shane Monks O'Byrne

- Sep 3, 2022

- 27 min read

Updated: 7 days ago

Grounding or earthing your campervan is an essential step when setting up your electrical system. There's a lot of contradictory information on how to set up the ground in van conversion electrics. In this article, we'll explain it all in full. We'll look at the types of ground, what appliances we should ground, and how we wire up ground in our campervans.

Index

Shane, the founder of The Van Conversion, is a campervan professional and NCC-certified electrical installer. Since 2020, he’s lived on the road full-time, completing several van builds along the way. He’s the author of Roaming Home and the creator of The Van Conversion Course, which have helped thousands build their own vans. Shane also writes The Van Conversion Newsletter, where he shares hands-on tips and practical insights. He’s passionate about empowering others to make their vanlife dreams reality.

This post contains affiliate links, which means that if you click a product link and buy anything from the merchant (Amazon, eBay, etc.) we will receive a commission fee. The price you pay remains the same, affiliate link or not. By using these links, you are helping me to continue writing free educational content! To understand our policies on content, affiliate commissions, and liability, please review our Terms of Use.

Did you know you can get a free electrical wiring diagram by signing up for The Van Conversion Newsletter?

What is Ground?

Ground (or earth) seems to mean different things in different contexts, hence the confusion over the term (especially in the world of van conversions). For instance, ground to an electrician can mean something different than to an electronics engineer.

Proper grounding is a critical safety precaution across the world of electrics. We ground electrical equipment so that wiring failures don't raise voltage or current to levels that could start a fire or shock you. Ground is a low-resistance pathway for electricity to follow to your fuses and breakers if there's a fault in your system. Instead of continuing to flow at dangerous voltages through your electrical system or through a short circuit, electricity instead flows through the ground to your fuses or circuit breakers which will quickly interrupt the power supply. Thus, grounding works together with proper fusing to make sure your electrical system fails safely if there's a malfunction.

As we know, a circuit must be complete for current to flow (think of a simple DC system):

We can use ground as an alternative circuit return path in case something goes wrong in our main circuit:

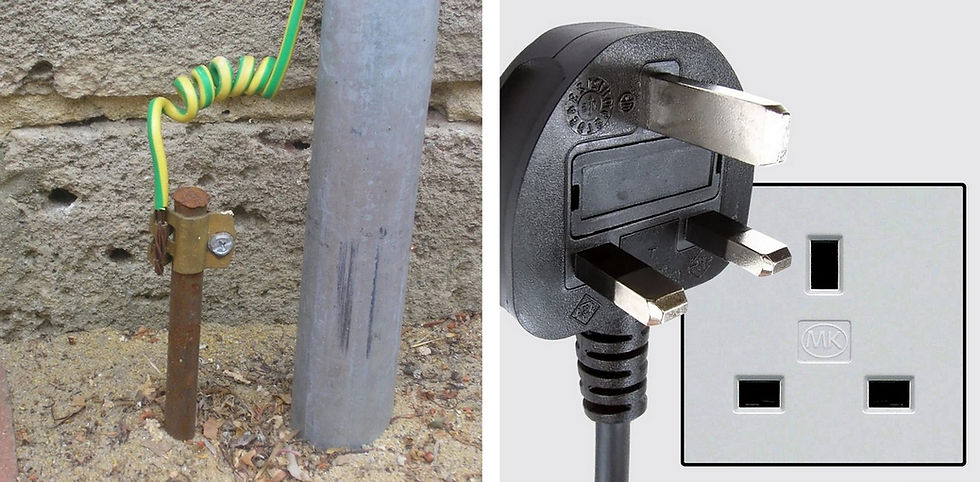

In buildings, this return path routes stray electriciy into the Earth, whence the term 'earth ground' for domestic electrical systems.

The Earth is a huge mass into which electricity can safely disperse, and it's the most convenient place to send electricity if a wiring fault would otherwise cause it to melt cables and cause electric shocks. Physically, this earth ground is a copper rod driven into the ground somewhere on the outside of the house. It's the same principle as a lightning rod running from the top of a church steeple into the Earth.

In the world of van conversions, we don't have the luxury of routing electricity into the Earth because our electrical systems are on wheels. Instead, we route electricity into the van's metal chassis; this connection is called chassis ground.

The chassis acts like a low-resistance path for electricity to return to the fuses and breakers we've installed. These fuses and breakers then quickly detect abnormal electricity flow and trip, interrupting the electrical supply.

Why Do We Need a Campervan Ground Connection?

In summary, a chassis ground connection in your van is important for the following reasons:

A Solid, Low Resistance Fault Path

If a live cable gets damaged and touches the van's body, you've now got a short circuit to the van's metal body. Without adequate protection, you're now energising the whole van's metal body with whatever voltage and current the damaged cable is carrying. This would deliver a nasty shock if you were to touch exposed metal, and could start fires as the damaged wire heats up due to the fault.

By bonding the DC negative battery terminal to the chassis at a ground point, the electricity shorting through the van's chassis now has a low resistance path back to the battery. Now, the high current comes back to the battery and quickly trips your big battery terminal fuse/breaker, cutting the electricity supply. A good DC ground connection is essential for letting your terminal fuse/breaker do its job.

AC ground relies instead on protection devices called RCDs, discussed later in the article. These devices detect current leaking to your van's chassis from a damaged cable, and cut the AC supply. Whether it's AC or DC, grounding ensures your protection devices work correctly, keeping you safe from electric shocks and fires.

Safety and Reliable Performance for Electrical Equipment

Many crucial components in your electrical system assume a common ground reference to the chassis; it's a sort of 'electrical baseline' against which they compare the electricity they're receiving and metering out. Devices that expect a chassis ground reference include:

Battery monitors and BMSs

Without a reliable ground connection in your electrical system, these devices can end up producing floating voltages, inaccurate readings, and generally unstable operation with voltage spikes and electromagnetic noise potentially damaging sensitive components.

Ground as a Convenient DC Negative Connection

A potential non-emergency purpose for a ground connection is as the negative DC return to your leisure battery. Because of the normally low voltage of 12V DC appliances, it's possible to just wire the negative terminal of every DC circuit to the nearest exposed chassis metal. Electricity can flow through the chassis back to the leisure battery's negative terminal, which is also simply connected directly to a chassis point. This used to be standard in older van builds, where DC appliances were lower in power and fewer in number. However, as the number and power of DC appliances in campervan builds has increased, the practice has been phased out, and we can't recommend it for the following reasons:

The high number of individual DC circuits in a modern van build makes it unfeasible for each one to be wired to its own standards-complying ground point

Ground points with constant current flow can cause corrosion of chassis metal as the metal around them is slightly ionised

Constant current flow through the chassis interferes with the need for modern, sophisticated DC appliances to have a basic reference voltage for proper functioning

One context where we do still commonly use the chassis as the negative return path is with DC-DC/split chargers. Many DC-DC and split chargers don't have a dedicated wired negative connection back to the alternator, instead using a negative connection to the chassis as the return path.

Standards and Compliance

Finally, a proper DC ground connection is required by electrical standards, and you risk failing your van's campervan certification without one. BS 7671 Section 721 (and BS EN 1648-2) both call for protective bonding between DC negative and the vehicle chassis for exactly the above reasons.

BS 7671 and NEC Guidelines for Grounding in Van Conversions

Proper grounding in your campervan electrical system is essential for both safety and compliance. Below are the key regulations from BS 7671 (UK) and the NEC (US) that directly apply to grounding in van conversions.

BS 7671 - UK Wiring Regulations

Section 721.411.3.1: Protective Earthing and Bonding in Caravans and Motor Caravans

All exposed conductive parts, such as metal appliances or components, must be properly earthed. The chassis of the vehicle serves as the DC ground for the 12V system, providing a return path for current.

For the AC system (shore power), a separate AC earth must be connected to the vehicle chassis, and it must be isolated from the DC ground. This prevents any crossover between the AC and DC earthing systems, ensuring the systems remain safe and separate.

Regulation 543.2.7: Earthing Conductors and Connections

Ground connections in campervans must be both permanent and accessible. For instance, your main ground point should not be hidden behind cladding or insulation to allow for inspection and maintenance.

Use a suitable earthing conductor that is sized appropriately. The minimum cross-sectional area for a DC grounding cable must be at least as large as the main DC positive cable, and for AC grounding, the green/yellow cable must comply with the minimum sizing set out in Regulation 543.1.

Regulation 411.3.2.1: Protective Earthing of Electrical Installations

Any connection to shore power (AC) must have a protective earthing connection, which bonds the AC system to the van’s chassis. The earthing conductor should run directly from the consumer unit to a dedicated AC ground point on the chassis.

It is crucial that RCDs (Residual Current Devices) are installed in the AC system to ensure safety, as they detect faults and disconnect power if a ground fault is detected.

Regulation 411.4.2: Earthing Systems for TN-S and TN-C-S Installations

If your campervan is connected to a TN-S or TN-C-S earthing system via shore power, ensure the earthing conductor from the electrical installation is connected directly to the main earth terminal at the van’s consumer unit. The system must include protection against faults that may occur due to a disconnection or interruption in the supply earth.

National Electrical Code (NEC) - United States

Article 250.136(A): Chassis Grounding

The chassis of the vehicle must be used as the DC ground. All 12V electrical components, such as the negative bus bar, inverter, and batteries, should have a direct connection to the chassis ground.

For the AC system, the grounding conductor from the shore power should also be connected to the chassis via a separate ground point to ensure the system has a reliable path to ground.

Article 250.4(A): General Requirements for Grounding and Bonding

The grounding system must establish a low impedance path to safely conduct any fault currents. This includes both the DC negative ground and AC ground, ensuring that fault currents do not endanger users or equipment.

Article 551.56: Grounding in Recreational Vehicles (RVs)

For systems using shore power, the NEC mandates that the AC grounding conductor from the shore supply be connected to the chassis. The AC and DC systems should have separate grounding points to avoid interference between the two systems.

Install Ground Fault Circuit Interrupters (GFCIs) on all AC outlets, particularly those near wet areas or external sockets. These devices will cut power if they detect a ground fault, ensuring user safety in case of faulty wiring or exposure to moisture.

Article 250.122: Sizing of Grounding Conductors

The grounding conductors must be sized appropriately according to the largest conductor in the system. For example, the grounding wire should be no smaller than one size smaller than the largest conductor connected to the battery or the system.

Article 250.140: Grounding for Inverter Systems

Inverters and their AC outputs must be grounded separately from the DC system. The inverter chassis should have a connection to the vehicle ground, and the AC neutral-to-ground bond must only occur at one location (typically in the inverter or the shore power connection). Multiple neutral-to-ground bonds can create ground loops, leading to unsafe voltage differences.

Key Principles of Grounding in Campervans

DC Ground: The negative terminal of your leisure battery and all 12V DC components should be grounded to the chassis. Use a negative bus bar to consolidate connections, and wire the bus bar back to the van’s manufacturer-provided chassis ground point or create a new one by securely bolting into bare metal. We'll talk about how to implement this later in this article.

AC Ground: AC systems (such as shore power and inverters) must be grounded separately to avoid cross-currents with the DC system. Use a dedicated AC ground point on the chassis for appliances like the inverter and consumer unit.

Ground Fault Protection: Install RCDs (UK) or GFCIs (US) to protect the AC system from ground faults. These devices disconnect power in the event of a fault, safeguarding the system from electrical hazards.

Accessible Ground Point: Ensure that your ground point is accessible for inspection and maintenance. Use green/yellow cables for AC ground and appropriately sized cables for DC ground, per the BS 7671 and NEC guidelines.

AC Ground vs. DC Ground

The main difference between AC and DC ground is that no current should flow into AC ground during normal operation, while all current should flow into DC ground. Why?

DC appliances don't have a "ground" per se, because the negative battery terminal (which people sometimes call "ground") is itself at the same electrical potential as the chassis. The negative terminal of your leisure battery is ground for DC appliances.

Which Appliances Should I Ground in my Van Conversion?

Certain elements must be grounded in a campervan:

Starter battery (should be grounded already)

Negative DC busbar - this grounds your leisure battery and the other DC components in the electrical system

Shore power (EHU) consumer unit (must be grounded per BS 7671:2018 – Section 721 regulations to a separate AC ground)

Others might need grounding depending on their construction. Consult the manufacturer’s guidelines:

MPPT

Battery chargers and split chargers (separate AC ground)

Inverter and inverter consumer unit (separate AC ground)

It is particularly important that you check the manufacturer’s guidelines as it relates to grounding your inverter (and the related consumer unit, if required), as grounding advice frequently changes with the manufacturer and how the inverter is built. As a general rule of thumb, each component in your electrical system should be grounded, unless the manufacturer’s instructions say otherwise.

It is important that all your grounds are connected together (ie. to a single ground point) to avoid ground loops. A ground loop is a closed conductive loop that will slowly but surely drain your batteries.

The DC ground and AC ground should run to separate ground points - with no crossover between the two. This means that the inverter and shore power consumer unit run to a dedicated AC chassis ground.

Grounding 230V/110V Plug Sockets: Consumer Units and Residual Current Devices

Any plug sockets that are fed by shore power or an inverter must be wired into a consumer unit (called a breaker panel in North America) to ensure safety and compliance with BS 7671 (UK) and NEC (USA). This is an important part of grounding your electrical system.

A consumer unit contains a Residual Current Device (RCD) (or a GFCI in North America) which detects when electricity is leaking to ground due to a fault and disconnects the circuit. It also contains a miniature circuit breaker, which protects against overcurrent and short circuits.

Neutral Earth Bonding in Inverter/Chargers

It's important to note that an RCD will not work if there's a fault in the operation of an inverter/charger unless there is a neutral-earth bond incorporated into the circuit. Thus, neutral-earth bonding is required under UK and US electrical regulations.

The Victron Multiplus and Quattro series of inverter/chargers incorporate neutral-earth bonds by default. If you don't have a Victron inverter/charger, you have to set up a neutral-earth bond yourself. Take a look at this excellent video from Cleversolarpower for a summary of neutral-earth ground works and why it's important:

When the inverter/charger is connected to shore AC power the AC input relay is closed and at the same time, the earth relay is open. The AC output system relies on the AC power supply to provide the neutral-to-earth link. This link is needed so the RCD in the AC output circuit is operational.

When the shore AC power supply is disconnected, has been turned off, or has failed, the AC input relay opens. When the AC input relay is open, the installation does not have a neutral-to-earth link anymore. This is where the neutral-earth relay that comprises a neutral-earth bonding closes. As soon as the earth relay closes, the inverter/charger has made an internal neutral-to-earth link. This link is needed so the RCD in the AC output circuit is operational.

This is why neutral-earth bonding is important; it maintains an earth connection in the inverter/charger even when the shore power earth connection is disconnected.

Once your AC plug sockets are wired into consumer units, the consumer units are ready to be wired to your AC ground point. Let's look at how to install ground points in your campervan.

How to Install Ground in a Van Conversion

The first step is to decide where your ground point will be. All vehicles have ground points pre-built into the chassis. A quick Google for your van's ground points should show you where they are. Per the BS7671 regulations, you should keep the ground point somewhere accessible, i.e. not behind cladding, insulation, or furniture.

Sometimes, you may want to make your own ground point if existing points are in an awkward place.

Installing a Campervan Ground Point, Step 1:

Choose your ground point location. It should be on an unobstructed part of the van's metal chassis which you'll be able to keep accessible for maintenance and inspection. Your ground cables should be kept as short as possible, so choose a spot near where you'll be installing your batteries, solar charge controller, DC-DC charger, inverter, and shore power supply.

Sand down the paint at your chosen ground point. This gives a clean connection point against the bare metal. Then, drill a hole big enough for an M8 bolt into that sanded patch of metal.

Step 2: Prepare Your Ground Cables

Size your ground cables appropriately, and remember that ground cables should exclusively be green and yellow, to differentiate them from all other cables in your system. Once you have your cables chosen, select the right-sized M6 ring terminals for these cables. Strip the ends of your cables with wire strippers, slip on a length of heatshrink tubing, and place the ring lug onto the stripped cable end.

Use a crimping tool to crimp the lug in place. The cable for your common DC ground might be very big, and you might need a specific big crimping tool; this is the one we used.

Finally, slide the heatshrink tubing up onto the lug's metal sleeve and use a heat gun to shrink it tightly around the end of the cable.

Step 3: Assemble Your Ground Point

You'll be combining your ground bolt with a star tooth lock washer and a nut. The toothed washer goes directly against the metal, where it will bite in and ensure good contact. The cable lugs will sit between the washer and the bolt head, and the nut goes on the tail of the bolt on the other side of the chassis hole.

Tighten the bolt hard to ensure good contact through the stack. Based on 70% of the proof load of standard zinc-plated bolts, we recommend a tightness of 8kN (10N·m) for M6 bolts, 15kN (24N·m) for M8 bolts, and 24kN (47N·m) for M10 bolts. If you're using stainless steel bolts, the numbers are lower: 6kN for M6, 12kN for M8, and 18kN for M10. Apply some Vaseline or a similar product to the whole ground point assembly to discourage corrosion, and make sure you support your cables; their weight shouldn't be hanging from the ground point itself.

Negative Busbar as Common DC Ground

Instead of running appliances individually to the ground point, we typically use a negative busbar as a common ground for all DC components that need grounding. All DC grounds run to the negative busbar and the negative busbar runs to the ground point. Best practice is to connect your heaviest loads to the central connection point on your busbar, and to connect lighter loads on the outer connection points:

Do not run AC ground to your negative DC busbar. If you want to run AC ground to a busbar, it should go to a new dedicated busbar termed the 'earth busbar'. The negative DC busbar should be wired back to the vehicle manufacturer-assigned negative connection point on the chassis. The earth busbar should be wired to a newly created mains ground point somewhere on the chassis.

Wire Size

Guidelines state that the DC chassis ground cable can be no smaller than one size smaller than the largest wire in the system. In practice, without going into too much detail, your best bet is to size your common DC ground cable the same gauge as your positive battery cable. Keep this DC chassis ground cable as short as possible to minimise resistance, and make sure chassis ground point is clean, bare, tight, and corrosion-protected as instructed in the previous section.

Next, there are individual DC devices that might need to be grounded independently of the negative DC busbar. For example, the Victron Orion XS 50A DC-DC charger and the SmartSolar 100/50 MPPT solar charge controller that we're putting in Shane's new van both need dedicated ground connections from their metal cases. All DC ground connections should be kept as short as possible and connected to the same ground point. The rule of thumb for these ground points is to use a cable that's one size smaller than the positive supply cable running to the device.

Finally, 230V AC circuits only need to be grounded with thin cables, as the high voltage means current is very low. 2.5mm cable is all that's needed. In North America, ground cables are larger due to the lower voltage of mains electricity; go with 12 AWG (3.31mm).

The Technical Principles Behind Ground Wire Sizing

It's safest to follow the above rules of thumb in most cases. However, if you'd like to better understand the principles behind these rules of thumb, read on.

When we set up these ground connections, we're we're protecting ourselves from the worst-case fault occurring in our DC system; that is, a short circuit between the battery's positive terminal and the van's metal chassis. In this case, the whole battery would discharge very quickly through the chassis via the negative busbar and the negative busbar ground. The big circuit breaker at or near the battery's positive terminal would trip and stop this short, but the negative busbar ground cable needs to withstand the high load until that trip happens without melting or catching fire.

That’s why this ground cable has two competing requirements: it needs low resistance (so the battery fuse receives a big enough fault current to trip quickly), and it needs enough copper to survive the fault energy until that trip happens.

In theory, you can size this using the adiabatic (I²t) principle, which links conductor size to fault current and clearing time:

Where S is the cable cross-section (gauge), I is fault current, t is the time the battery fuse or breaker takes to trip, and k depends on conductor/insulation temperature limits. The problem is that the particularities of a van installation make the inputs hard to know with confidence. Fault current depends on battery internal resistance, BMS limits, wiring and joint resistance, the chassis return path, and even the character of the short circuit contact itself (bare metal vs. paint or an arc). Clearing time depends on the exact fuse/breaker characteristics, and many fuse datasheets don’t publish time-current curves. Even Victron don't include this information for their fuses.

That’s why most real-world van builds use conservative rules instead of deep calculations: we size the bond cable the same as the main battery cables, keep it short, and make the chassis connection clean, bare, tight, and corrosion-protected. Oversizing isn’t just extra safe; it actually lowers resistance, which tends to increase fault current and helps the main fuse or breaker trip faster.

Ground Fault Protection - RCDs, GFCIs, and RCBOs

We talk about RCDs, GFCIs, and RCBOs in our article on shore power connections, but it's relevant here too as they're essential components of safe grounding in AC circuits.

Because our AC ground is the van's chassis, we need to make sure that if AC current does leak to ground, it's interrupted quickly. As in domestic applications, an uninterrupted leak to ground can cause wires to overheat and melt; a dangerous fire hazard. However, in a campervan, an AC ground fault will also electrify the van's chassis at 230V, giving you a very dangerous shock if you touch any exposed metal. The same danger arises if a dislodged wire inside an AC device touches the device's metal case; here, it's the case that becomes dangerously electrified. RCDs and RCBOs ensure that any ground/case leak is quickly interrupted.

RCD: Residual Current Device; a GFCI or Ground-Fault Circuit Interruptor is the North American Equivalent. Protects you from electric shock when it detects current leaking to earth.

MCB: Miniature Circuit Breaker. We use these instead of fuses in AC systems to protect against overload and short-circuit. Read more about them in our shore power article.

RCBO: Residual Current Breaker with Over-current. Combines an RCD with an MCB in one device, providing comprehensive protection for AC systems.

RCDs, GFCIs, and RCBOs all work by continuously comparing the current difference between the live and neutral wires in your AC circuits. In a correctly functioning circuit, this difference is zero. If some of this current leaks to ground, a metal case, or a person, the difference between live and neutral changes. An RCD or GFCI detects this change, trips, and interrupts the circuit.

UK/EU: RCD

These are commonly installed as part of the consumer unit protecting a set of AC circuits. An RCBO is a device that incorporates an RCD's ground leak protection with an MCB's overcurrent protection. Many modern consumer units exclusively use RCBOs.

North America: GFCI

The US equivalent of a UK/EU RCD: it trips when it detects current leaking off the intended live–neutral path (typically to ground or through a person). In US RV and van builds, GFCI protection is often provided at the receptacle (a GFCI outlet) or at the breaker (a GFCI breaker), rather than by a single “main RCD” protecting multiple circuits.

Sizing: you don’t choose a GFCI by milliamps in the way you choose an RCD rating. Class A GFCIs are effectively standardised around a ~5 mA trip level. You size the GFCI's amp rating using normal breaker logic based on wire gauge and expected load; read more about that in our fusing article.

If you're installing an AC mains socket, install a GFCI outlet with an integrated GFCI. If you're hardwiring an AC appliance, install a standalone GFCI alongside the breaker. Not all AC circuits need to be equipped with a GFCI; only those in 'wet' areas like your garage, kitchen, or the exterior of your van.

RCD Type: AC vs. A

RCDs come in two types; type AC and type A.

Type AC: only capable of detecting sinusoidal AC currents

Type A: capable of detecting sinusoidal and pulsating DC currents

Many modern AC devices actually internally rectify the AC to a DC supply and use this DC to supply downstream components and devices. This means that a leakage to a case or ground may not take the form of the clean sinusoidal current that a type AC RCD is designed to detect. Therefore, you should only install type A RCDs in your campervan.

Double-pole vs. Single-pole RCDs

The polarity of an RCD refers to whether it cuts both the live and neutral connection in the event of a ground fault, or only the live connection. BS 7671 requires that both live and neutral are disconnected (ie. double pole isolation).

That requirement can be met in two valid ways:

Option A: Double-pole RCD + single-pole MCBs

Option B: Single-pole RCD + double-pole MCBs

In practice, almost all consumer units for vans use:

Double-pole RCD

Single-pole MCBs

RCD/RCBO Ratings: What to Use in Your Van

RCDs and RCBOs have two different headline ratings:

Earth-leakage sensitivity/shock protection: this is the detected live-neutral current difference at which the device will trip. The units are given in mA (milliamps).

Continuous current rating: this is the normal load current that the device can carry continuously. The units are given in A (amps).

In the UK and EU, all RCDs/RCBOs must have a sensitivity of 30mA, trip in less than 40 milliseconds at 5x the sensitivity rating, and trip in up to 300 milliseconds at 1x the sensitivity rating per BS7671 campervan safety standards.

If you're sizing an RCD/RCBO's continuous rating to protect your AC system at the shore power supply, size it based on the maximum shore power supply you're likely to encounter. In the UK and EU, 16A supply is the highest you'll get, so a 40A RCD/RCBO is fine. In North America, you'll see 30A and 50A supplies, necessitating a 75A or 120A RCD/RCBO, respectively.

If you're sizing RCBOs to protect individual AC circuits (we discuss this in the next section), the specified continuous rating actually refers to the internal MCB's trip rating. In this case, follow the rule for fuse sizing: choose a size slightly smaller than the amp rating of the wire being fused. Read more about this in our fusing article.

Two Practical Ground-leak Protection Setups

In a campervan, we need to set up ground-leak protection that trips fast enough and which disconnects both live and neutral. We need to make sure all AC circuits have the same level of protection. That leaves two sensible layouts. Note again that in all cases, RCDs and RCBOs will only work correctly if your inverter/charger is neutral-earth bonded.

Option 1: One upstream double-pole RCD and downstream per-circuit MCBs

In this setup, we install a 2-pole type A 30mA RCD immediately downstream of the AC distribution, which is either the shore power inlet or the inverter. We then install 2-pole MCBs for each downstream circuit. These devices can be integrated into a consumer unit for tidiness.

This gives the whole AC system top-level ground-leak protection and protects each individual circuit with its own overcurrent device.

Pros

Lowest cost, simplest consumer unit.

Simple to wire and expand by adding another MCB circuit.

Cons

One ground-leak anywhere trips the whole AC system.

Harder to troubleshoot which circuit is causing a ground fault.

More sensitive to cumulative leakage: lots of modern electronics each leak a tiny amount to ground by design (modern device chargers, induction hobs, inverter/chargers). The totalled leakage from many such appliances can approach the RCD's trip threshold. Then, a small transient leak which can occur on device plug-in or a damp hook-up connection can cause an unexplained trip.

If you have plug sockets powered directly from the shore power inlet, you'll need to protect these with their own RCD and MCB, doubling up on consumer units.

Option 2: All-RCBO Consumer Unit

In this setup, we do away with the initial RCD and instead protect each individual circuit with its own RCBO, providing each circuit with its own ground-leak and overcurrent protection. These RCBOs should always be type A, 30mA, and double-pole.

Pros

A fault on one circuit does not kill everything.

Easiest troubleshooting: the tripped RCBO points to the circuit.

Less nuisance from cumulative leakage because leakage is “partitioned” across circuits.

No change if you have plug sockets powered directly from the shore power inlet; these have their own RCBOs like the rest of the circuits in your system.

Cons

Higher parts cost, bigger consumer unit, more neutral wiring.

Choosing Between Single-RCD and All-RCBO Setups

Option 1, the single-RCD, per-circuit MCB setup is preferable when:

We have a simple AC setup with up to 3 AC circuits

Cost and simplicity are a priority

The main problem with this setup is the fact that it trips the whole AC system if one circuit faults or if cumulative leakage tops the RCD's threshold. If you've only got a couple of circuits, troubleshooting them is simple and cumulative leakage won't be an issue.

Option 2, the all-RCBO setup is preferable when:

We have more than 3 AC circuits running modern electronics

We have circuits which must stay on, like those running medical devices

Minimal downtime is a priority

If you have multiple AC circuits, cumulative leakage and nuisance trips are much more likely to be an issue. An all-RCBO setup ensures one faulty circuit doesn't trip the whole system, prevents trips due to cumulative leakage, and makes troubleshooting quick and easy. It also ensures that essential medical devices won't lose power in the event of a fault.

A Word of Warning: Rusty Ground Connections

Personal experience has made me think more carefully about my ground point. A few years ago, my leisure batteries weren't charging from my split charging system. I changed the fuses, rewired the busbars, replaced cabling, and nothing changed. I swapped out my voltage-sensitive relay for another one, and even changed the leisure batteries themselves. Still no joy. Eventually, I remembered to investigate my ground point. Finally, here was the culprit: my ground point was rusted to oblivion. Replacing it fixed the issue.

A split charger relies on an intact link between the alternator, starter battery, leisure battery, and negative chassis ground. If this link is severed by a rusted ground connection, the split charger can't tell when the leisure battery is less than full and won't switch to charging it.

I never thought to check my ground point because it was buried under furniture and plumbing and really hard to access. Per BS7671 regulations, make sure your negative chassis ground is easily accessible, and check on it every year, applying dielectric grease and rust treatment if needed. As your ground point becomes more rusted, the resistance increases more and more until eventually it can become a fire hazard (resistance = heat).

The Campervan Isolation Transformer: A Solution for Unreliable Campsite Grounds

When we plug our campervan electrical system into the mains shore power supply at a campsite, we're normally protected from electrical malfunctions by that shore power supply's earth ground connection. It's essentially a domestic mains installation, with the same type of earthing and protection. However, campsite earth ground isn't always reliable. Older and rural campsites, especially in Southern and Eastern Europe and beyond, festivals, and farm stops might not always have a sound protective earth.

If you're plugged into a hook-up with a dodgy earth connection, the van’s metalwork can “float” at a nuisance voltage. People often describe this as a tingle when touching a chassis point, wheel, or sink, especially when standing on wet ground [source, source]. A chassis floating at a voltage higher than ground might cause your electrical components to malfunction and interferes with the function of your residual current devices. An RCD that's not functioning properly is dangerous in the event of an electrical fault, which is why dodgy campsite grounds are a problem.

An isolation transformer can reduce your dependence on the campsite’s earth quality by galvanically separating the shore supply from your onboard AC system. Done correctly, your van’s onboard system can be bonded and protected so that a fault to metal produces the kind of imbalance an RCD is designed to detect and disconnect.

If you mainly use reputable sites, and only occasionally, an isolation transformer is usually overkill; focus on a correctly built van AC system (RCD/RCBO protection, correct bonding, good inlet and cable). If you live on hook-up and regularly move between unknown hook-ups (long cross-border trips, for example), an isolation transformer is a sensible upgrade. However treat it as something you design your system around from the get-go rather than an add-on, and have it installed by a qualified electrician who specialises in campervan AC systems.

Here is how to wire a Victron Isolation Transformer for a campervan with a Victron Blue Smart Charger:

And here is how to wire a Victron Isolation Transformer with a Victron Multiplus:

A final note; there is talk on forums of wiring up a homemade earth ground rod that you take with you and drive into the ground at hook-ups. In principle, this would seem to work like a domestic physical earth ground connection, bypasing the need for an isolation transformer. In practice, depending on what's going on underground in your campsite, sandy, gravelly, and rocky ground can result in a very high-resistance contact here. High resistance means current won't flow in the event of a fault, meaning your RCDs won't trip. This type of setup looks safe but isn't, giving you a false sense of security. Don't be fooled.

Grounding Copper Pipes in a Campervan

If you use copper pipe for any part of your water (or heating) system, it actually needs to be grounded itself due to its high electrical conductivity. If an AC fault energises that pipework (either due to damaged AC cable physically touching it or due to an AC fault elsewhere energising it via the chassis), the pipe can sit at mains 230V potential. If you touch that pipe and a piece of metal that's at a different potential, the voltage difference flows through your body, delivering a potentially lethal shock. Grounding copper pipes is standard in domestic applications for this reason.

Grounding the pipework means it’s held at the same potential as the van’s protective earth, and in a fault it encourages a high enough fault current to make the RCD trip instead of leaving the pipe live.

How to Ground Copper Pipework

Bond copper pipework to the van’s main AC earth bonding point

Use a proper bonding clamp on bare, clean pipe.

Run a short green and yellow earth cable of 4–6mm² thickness to the earth point with a ring terminal, just like how you've grounded your other AC components

Conclusion

Grounding is an essential safety component of any electrical system, alongside fusing. If you're uncertain about your installation or how to best approach grounding, consult a professional electrician. It's best not to play around with your electrical system unless you're 100% sure of what you're doing. Check out our guides on electrical systems and electrical regulations to build on your knowledge, or consider our electrics course bundle.

Don't forget to subscribe to The Van Conversion Newsletter for everything you need to get started with your own van conversion (we'll send you a free wiring diagram when you join).

If you're looking for some guidance with your van conversion, you might be interested in our book Roaming Home, or in our online course The Van Conversion Mastery Course. You'll learn directly from our founder Shane how to convert a van into your dream home - no prior experience needed. Shane also offers one-to-one consultations, where he'll help you with any aspect of your build in a face-to-face video call. All consultations come with a free copy of Roaming Home and our Diagram Pack.

Finally, our Van Conversion Ultimate Guide lays out the whole van conversion process in easy-to-follow sections with tools, materials, and step-by-step instructions. It's the perfect companion for your van build.

Until next time.